Motor

Motor Fix-up

Most motor's don't really need maintenance, or modding! In general how they are made from the factory is close to ideal. So in general I don't recommend modding your hardball motor. But some people don't believe in factory standards and will do anything to push their parts from to 100% so if you are prepared to risk your motor in the quest for that last 1% extra then read on :-)

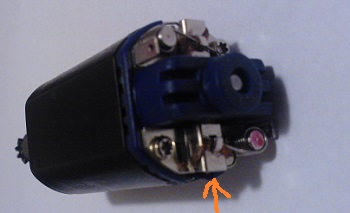

Motor sparks

Some motors have metal end bells (The end part where the wires are connected). If that's the case then electricity might go from the wires into the end bell (if not isolated) and spark from the end bell to the motor shaft. Instead of going to the brushes ... I have had one motor (An old Systema Speed motor) where this happened and it only happened when pulling insane amounts of amps. What you want to do if you have metal end bells, is isolate them from the electrical parts... Use a small peace of cardboard to put between the metal plate holding the brushes and the end bell (under the metal plate). Just unscrew the plate and put it under and re attach!

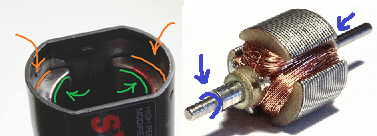

Motor Clean

Old motors collect dust and burn marks on the brushes and on the end of the rotor. What you want to do is remove the spring, and the brushes. And cut a peace of rubber as a square same size as the brushes. Put in inside the brushes holder and re install the spring... Turn the motor by hand some rotations (10-20 rotations) and then remove the rubber then the cobber at the end of the rotor should be nice and clean. Then just clean the brushes with the rubber and re install them... This cleaning should give a good connection from the brushes to the rotor end. This will ensure better connection, and reduce amps required to pull the motor.

Spacers

To make the motor perform at maximum then the rotor should be as close to the magnets as possible. Without touching! If the rotor hit the magnet everything may break! When the end bell is removed you can see how much it can move around from side to side. If there’s allot (more than a millimeter) of space add spacers to move the magnets closer to the rotor! The rotor itself should have a limited up down movement (when everything is assembled) add spacers to the rotor to limit movement. A perfect spacing limits the amount of power the motor needs to turn the gearbox, increasing speed and reducing amp draw in the battery.

Breaking in

When you buy a new motor you can just put it in the gun without doing anything. But if you like your new motor and want it to last longer, you should break it in. What you do, is take a SMALL battery 4.8 volts (NOT a standard hardball motor!) or so and run the motor on that for 5 min or around that. This makes sure the brushes set correctly and limits the stress on the brushes and rotor connection. But because that a hardball motor don't run at full speed (because of the tension from the spring) it's not really required. But doing so will make your motor last longer and run better right from day one.