Cylinder to barrel - Volume ratio

Cylinder volume calculation

The cylinder and piston pushes air into the barrel, and that’s what makes the bb fly. This process sounds simple, but when going into the details there’s allot more to it than just maximizing the amount of air. The 2 important factors are air pressure, and volume ratio. Getting good air pressure is a matter of a strong spring, and limiting leaks (see the air seal guide). So I won’t go into more details on that in this guide.

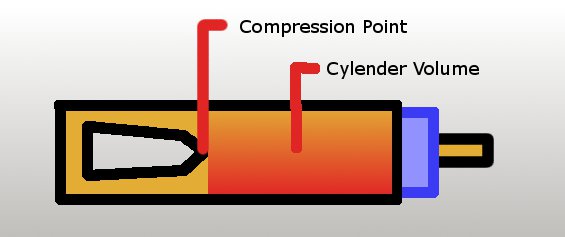

Key names

When you pull the trigger and the piston is released by the sector gear, then the piston starts to travel down the cylinder. From the point it passes the last hole in the cylinder it starts to compress air in front of it. This point is here referred to as “compression point”. The volume of air in the cylinder from the compression point to where it hits the cylinder head is the cylinder volume. And the inner barrel’s volume is just known as barrel volume.

Volume ratio

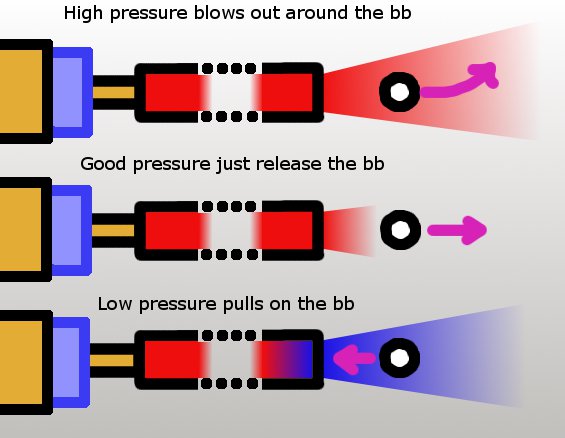

The ratio between the cylinder volume and the barrel volume is the volume ratio. This volume ratio (combined with air pressure) is what determines the speed that the bb exits the barrel. If the ratio is to low, then the bb will not be pushed by air the whole way down the barrel, so it’s not reaching its full potential speed. If instead the volume ratio is to high then at the point where the bb exit the barrel the air pressure behind the bb will still be very high. This high pressure will then shoot out around the bb, and apply spin in a seemingly random direction. It’s not as much spin as a hop up ads, but any uncontrolled spin will make the bb fly in another direction. So a too high ratio will affect accuracy.

Optimal ratio

There is no clear and simple way to specify what an optimal ratio is. That’s because there’s simply too many factors to give a simple answer. So instead I will try to give you some pointers that should lead you in the right direction. In general ratio values should be in between 1.5 and 2.5, and it’s better to be above than below. Long inner barrels tend to favor higher values of 2 to 3.5 because a too low ratio will have bigger affects in longer barrels than in shorter. So to make sure you get enough air into longer barrels you increase the ratio. Also precision barrels have a smaller inner diameter, so less air escapes around the bb, so they require smaller ratios but only around 0.1 to 0.3 less ratio…

Why not 1 to 1 ratio?

Many people have asked that question. And a 1 to 1 ratio should be perfect if you want to have the bb leave the barrel with zero air pressure behind it. But you don’t want that! What you want is to have the air behind and around the bb, to exit the barrel at exactly the same speed as the bb itself. Then you have a perfect gun where the air around the bb doesn’t push it off center, and at the same time push the bb down the entire barrel. But to achieve this you would need an air speed measurement devise with an extreme update rate, to measure air speed and match that to the bb speed of the gun. And that’s just too hard an expensive to be practical. So instead one should just make sure the air pressure is not to low, and an easy way to do this is to just look at volume ratios.

How to fix ratios that are off.

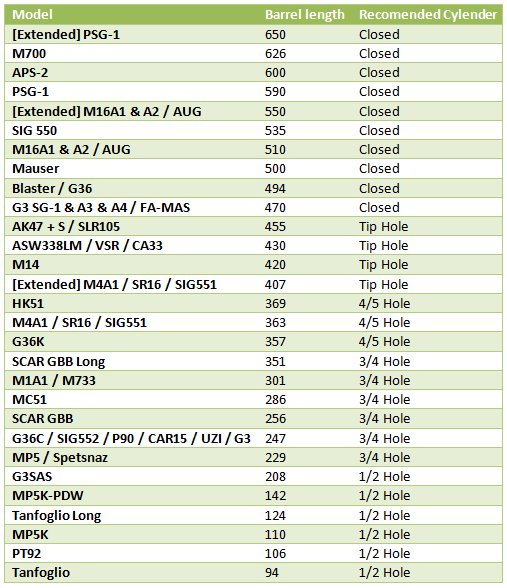

There’s 2 ways to change ratio. One way is to change cylinder size, the other is barrel size. To increase ratio you can get bigger cylinder sizes (one with holes longer up the cylinder, or bigger inner diameter) or shorten the barrel. To decrease ratio do the opposite, smaller cylinder volume or longer barrel. Also the inner diameter will affect the ratio, but only little. So I recommend playing with cylinder hole location and barrel length as the main thing.

The volume calculator on this page will help you find your ratio. But always make sure replacement parts fit in your exact gun model. You can also cut holes in your cylinder where you want them to be, but it’s hard to get right, and you may ruin the cylinder or piston if not done correctly.

Cutting cylinder holes

If you do decide to cut holes in the cylinder make teardrop shapes, because it helps the piston to slowly settle in the cylinder and more slowly build pressure. This decrease ware on the cylinder O-ring. And always make edges smooth using fine grain sand paper, so they don’t cut into the cylinder and o ring.

Also go check out the air seal guide, and the O-ring expansion guide. Both of them relates to air pressure. The barrel stabilization guide may also be useful if you are looking for accuracy. And if you have holes in your cylinder then the short stroke guide can help you increase speed an durability with limited impact by making the piston release from the holes instead of moving all the way back.